GTS-65 / GTS-65 HP

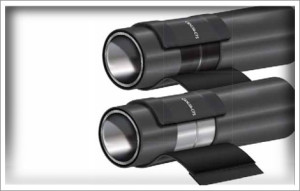

The GTS-65/GTS-65 HP system provides superior corrosion protection and excellent bonding on pipelines operating up to 65°C. GTS-65 has been designed with a unique adhesive technology that remains “open” longer than traditional adhesives. Also, special surface active agents allow bonding to lower surface energy coatings (such as polypropylene). As a result, lower preheat temperatures are required to attain true adhesive wet-out and superior bonding to PE, PP and FBE surfaces is achieved.

GTS-PP II

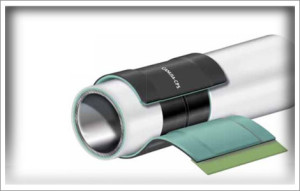

a Key offering within the GTS-PP product family, GTS-PP II uses Shawcor’s unique and patented. cross-linked polypropylene outer layer, along with a proprietary rapid-activation polypropylene copolymer adhesive advanced and liquid epoxy layer to deliver protection that far exceeds minimum industry standards,such as ISO, while offering significant installation advantages over the highest performing PP systems, that require higher installation temperatures.

MIS-65 / MIS-100

Corrosion protection of Girth-Welds under heated infill systems on offshore service environments.

MIS-65 and MIS-100 heat-shrinkable sleeves provide superior corrosion protection and effective long-term adhesion to pipelines operating offshore at temperatures up to 100°C (212°F). MIS-65 and MIS-100 sleeves are specifically engineered for use in combination with hot marine mastic Pour, polyurethane foam or other infill systems. MIS-65 and MIS-100 sleeves are resistant to the severe conditions of hot mastic pour operations and maintain their full set off anti-corrosion properties. MIS-65 and MIS-100 are fully compatible with a wide range of pipeline coatings, including PP, FBE, PE, Coal Tar and Tape.

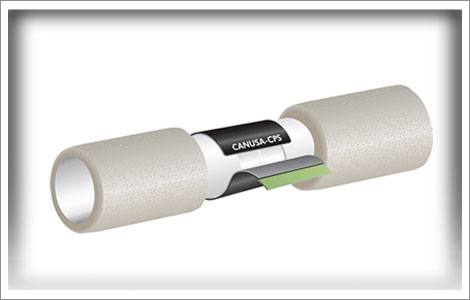

OFFSHORE/ONSHORE WRAPIDSHRINK SLEEVE KLON & KLNN

The Canusa wrapping Sleeve KLON and KLNN are one piece wraparound sleeves designed for corrosion protection of both offshore and onshore steel pipelines .These sleeves are designed using a High Density polyolefin backing for improved mechanical protection and either a thermoplastic hybrid or a high shear mastic adhesive for easy installation and high corrosion. protectionconsists of cross-linked polyolefin backing, coated with a high-shear mastic heat-activated adhesive which effectively bonds to steel substrates and common pipeline coatings, including polyethylene and polypropylene.

DDX

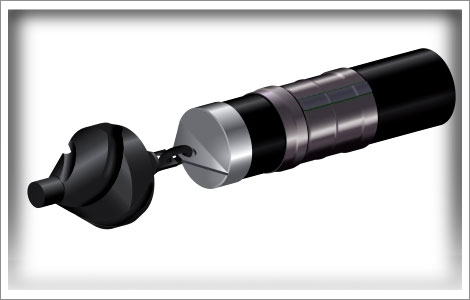

THE TBK-Directional Drilling Kits are high performance systems designed to protect welded joints on PE and FBE coated pipelines in directional drilling application.

DDX – Advanced girth-weld protection for pipes used in directionally drilled applications.

The DDX – Directional Drilling Kit is a PE mesh-reinforced high performance system designed to protect welded joints on PP, PE and FBE coated pipelines in directional drilling applications. This 3-layer system is the most recent evolution of Canusa’s leading edge joint coating technology.

HBE-95 / HBE HT

HBE-95/HBE HT is a state-of-the-art. 100% solids, two component epoxy coating system which has been specifically formulated as as pipeline coating. Applied to bare steel, HBE products are used for protection of pipeline field joint girth welds, valves and fittings, as a holiday repair material on FBE coated pipe or for pipeline coating rehabilitation.

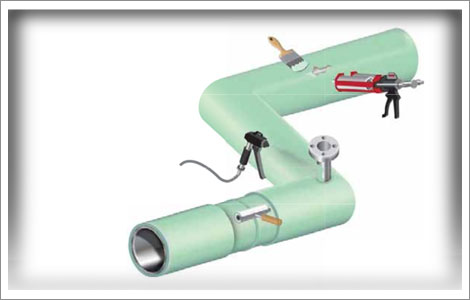

PIPELINE REPAIR PRODUCTS

Canusa pipeline repair products are used to add corrosion protection and/or fill voids in damage coatings. A full line of products provides the flexibility to make a variety of repairs to mainline coatings, ranging from minor coating damage to holidays and exposed steel.

[/column]

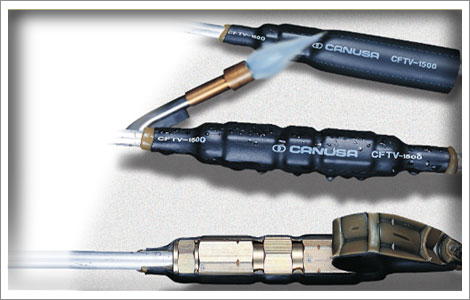

CFTV – Insulate Seal Protect

Heat Shrink tubing and adhesive liner combination that established the CATV industry standard for splice and connector protection.

Continuous operating temperature: -55°C to 110°C

FEATURE AND BENEFITS

- Craft friendly Installation

- Exceptional split resistance

- CFTV adhesive retain bond providing long term protection

- Selective stripability to meet CATV industry specifications

- Minimal heat required to produce error free installation without splitting

- Thermochromatic lines change colour to signal waterproof seal

- Shrinks and seals in half the time of alternative products

- Shrink ratio 3:1

- Continuous operating temperature: -557°C to 1107°C